Beer brewing session

I attended a beer brewing session yesterday, creating a beer with alot of "flower" character, since half of the hops wasnt added until the fermentation process...

Its at a café in Bali, where they sell coffee and beer products...

I ordered things from here before...

They offer courses in brewing, as well...

We got to se how the restaurant operates, and some process information in brewing techniques...some basic things...

grinding the malt...not too much not too little...

I ate some of it...

Then we put it into water...

HEre is a list of the portions we used, to get the characteristics of this beer...

We also tried some beers on the market...

The mix has to be filitered, but before that, it has to be aroung 65 degs celsius, to get enought character (Beta particles that creates sugar)...

More beers...

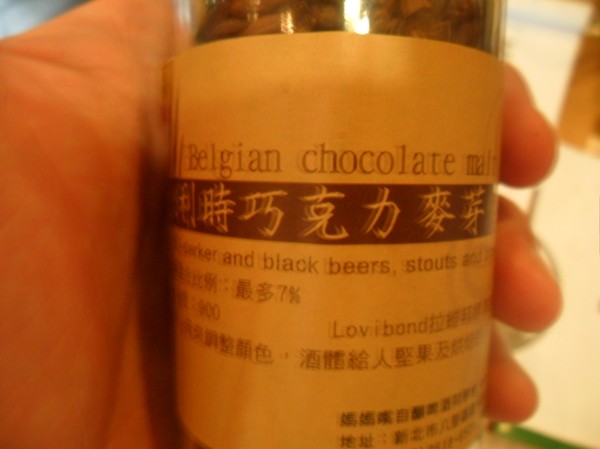

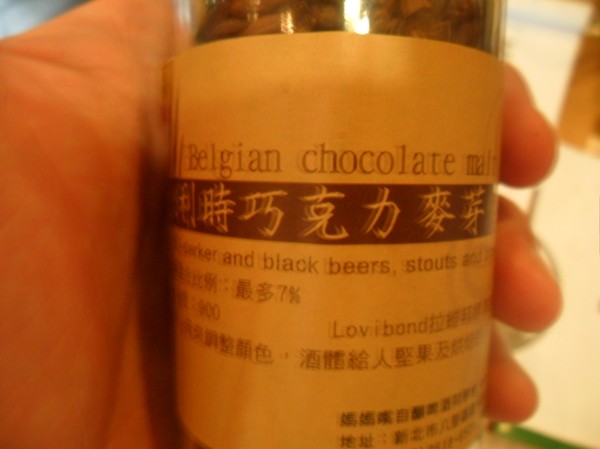

Some smelling and tasting of different kinds of malt...

This is interesting...chocolate..just like guiness....

Mixing again...I asked why we just dodnt pu the pot in the oven, on 65 degrees, instead of mixing over and over, to be in the temperature spann...but I didnt understand the answer...

Digital thermometer, i ordered one of these...but the delvery is delayed :S

Then more drinking...

And boil it up with hops for some hour...

And boil it up with hops for some hour...

And some theory...(in chinese)...

And more drinking...

Then, since we did not have time to wait for the whole fermentation prices (some weeks), this step was prepared in advance...

We got to try different kinds of beer (mostly depending on the hops, but also the malt)...

Then starting with the alpha particles, then the temperature has to be 70 degrees celsius...for a while...

looks and smells like porrige...

Still looking at the temperature...

Then it was time to filter the mix...

To get all the sugar out from the malt, we added some new hot water...

Nice buckets...Im using some lame milk bottles at home...

This is how the filter looks like...

And this is the cooler...same as my friends are using in sweden, when they illegally are making alcohol( over 20%)...

We also heated up bottles...

Butting in more hops...

We had 4 different kinds of hops...

It did not smell that much,,,

We continued with the pre prepared mix that was already fermented...while waiting for the boiling to be done...

We continued with the pre prepared mix that was already fermented...while waiting for the boiling to be done...

Then we used this pole to dry the bottles...

Home made things...

Bottles are done...

Ready to dry them...

And add some sugar...to the filtered porrige mix...(the hops usually adds bitterness to the beer, i usually prefer light beer, thats not bitter at all)...

Many bottles...

Then we were about to filter the mix again...

Tapping...

More tapping...

And now it was time to bottle it...

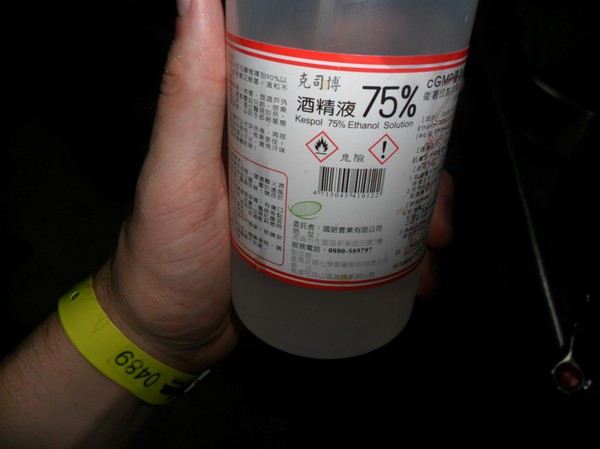

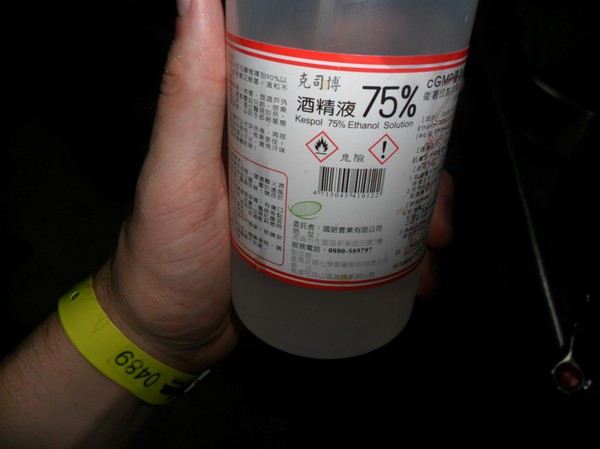

Alot of alcohole added to kill bacteria, this is an imprtant procedure...

And close the bottles...

A slow process...

Now the boiling was done, time for cooling...

We added more hops, to get a special flavour of this "reddish beer)...

And we also boiled the cupper cooler, so kill bacteria...

And in with cold water in the cupper cylinder...

It is important the the cooling goes fast...this took maybe 1-2 minutes, from 100 to 10 degrees...

We filtered the mix again...to get ridd of the hops...(Pijiuhua in chinese meaning: beer flower)...

And pour into a barrel for fermentation...(a super clean barrel)..., and some yeast was added...

Everthing was stored in Cl2, to kill bacteria...

Or sprayed with alcohole...

This nozzle was applied to prevent to high pressure...

We also used this advanced equipment to measure the sugar percentage...(about 20,000NT (5000SEK), most people are using analoge equipment for this part...

Kommentarer

Trackback